|

Home Page

Company Profile

Plant Capabilities

Quality Department

Conflict Free Policy

Customer Reports Area

Product Samples

Awards

RMCI Employee Policy Manual

RMCI Facts & Figures

Employment Opportunities

Contact Information

ISO Certificate

NQA.USA

| |

-

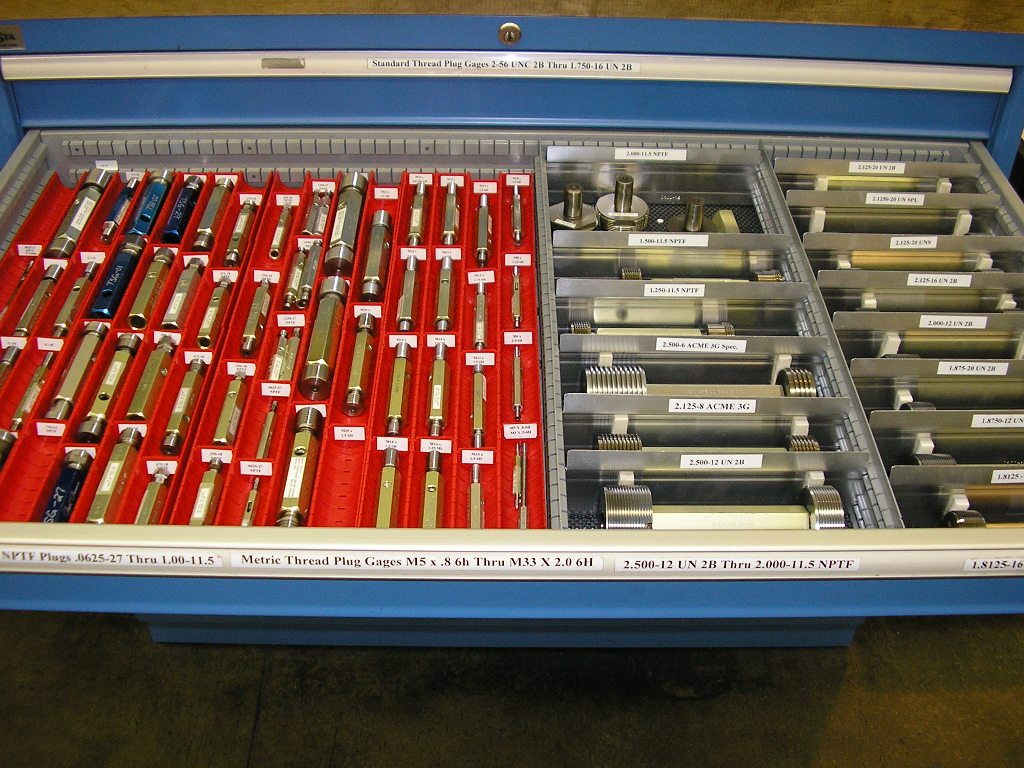

Inspection Capabilities:

Roberts

Manufacturing is totally committed to the goals of continual improvement and

100% customer satisfaction. RMCI has implemented a quality system to ensure

these goals are achieved. Our Quality Assurance personnel offer over 75

years of experience and are trained to our

inspection procedures. Customer requirements are communicated to all

levels of inspection and production. State of the art inspection equipment

is utilized by our Quality Assurance inspectors. Our Quality Department

calibrates over 800 gages internally. At all levels of

inspection, calibrated gages and equipment are employed. Major and

Miscellaneous Equipment:

- (1) Mitutoyo Bright Apex A-707 C.N.C. CMM

- (1) Sheffield Cordax 1808 with Brown & Sharpe

retrofit

- (2) Micro-Vu video measurement system

- (1) Federal FormScan inspection center

- (1) Van Keuren light box

- (1) Pratt & Whitney LabMaster gage calibration

machine

- (1) Federal-Mahr dual probe height measurement

table with dual probes

- (4) D-8000 Federal Dimensionair air gages

- (1) Certified Magnetic Particle Inspection

- Large array of height stands, indicators,

micrometers, calipers, thread rings, thread plugs, variable thread

measuring systems, surface and hardness testers, pin gages, and other

miscellaneous equipment.

|

ISO

9001:2015 CERTIFIED

ISO

9001:2015 CERTIFIED